Sustainability and Green Manufacturing Practices

As a leading company specializing in manufacturing rubber cords, PVC cords, plugs and kits, ETL, we understand the centrality of environmental protection and sustainability in modern manufacturing. Not only do we focus on providing superior performance electrical connectivity solutions, but we also incorporate green manufacturing concepts throughout our entire production process.

We are committed to ensuring our products’ high quality while minimizing our environmental impact, providing our customers with a longer-lasting, more reliable electrical connection experience, and working together to help create a sustainable future.

Environmentally friendly materials and design optimization

Our product design always follows the principle of “eco-design”, prioritizing the use of environmentally friendly, recyclable and low-carbon raw materials to ensure that our products minimize the impact on the environment throughout their life cycle.

Environmentally Friendly Material Selection

We use raw materials that meet international environmental standards, such as halogen-free PVC, TPE and PP, including recyclable polymers and lead-free alloys certified in accordance with the ISO 14001 environmental management system, in order to minimize the negative impact on the environment.

Low Carbon Design

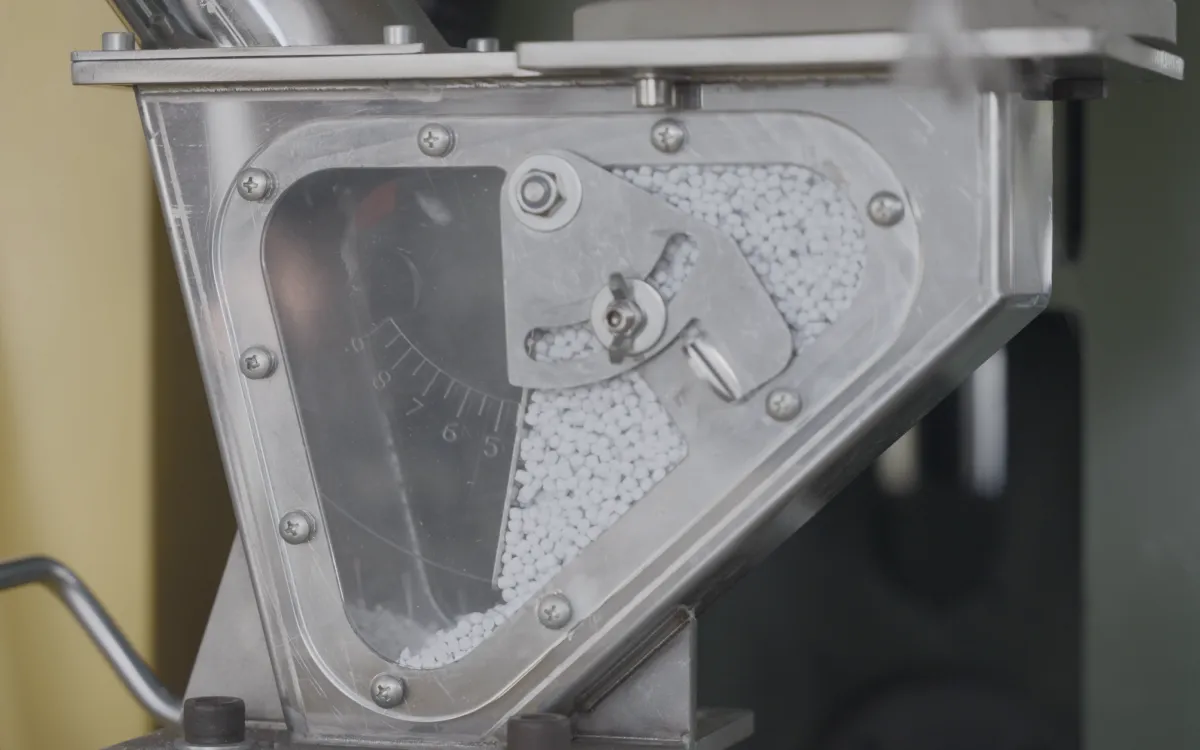

We use highly efficient injection moulding technology in our production to reduce scrap and ensure that every metre of cable meets high performance standards through strict quality control.By optimising the formulation of rubber and the production process, we effectively reduce raw material wastage and increase the life cycle of our products.

Chemical Harmlessness

Our products comply with the EU RoHS (Restriction of Hazardous Substances) Directive and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations, avoiding the use of harmful chemicals such as lead, mercury and other heavy metals.

Focus on Employee Health and Safety Management

WASUNG is certified to ISO 45001, the international standard for occupational health and safety management. We create a safe and healthy working environment for our employees, demonstrating our commitment to sustainable development and social responsibility. Through a comprehensive management system, regular risk assessments and training, we minimize accidents and health risks and promote green production and sustainable development.

Guarantees of Sustainability

ISO 17025 is an internationally recognized standard for quality management in laboratories and is particularly applicable to testing and calibration laboratories. In terms of sustainability, ISO 17025 accreditation helps WASUNG to ensure the accuracy and reliability of test results, while also improving compliance with product quality and environmental monitoring through standardized management practices.

*More accurate environmental impact assessment and performance testing

*Ensure product compliance with environmental requirements

Energy Saving and Efficient Production

We utilize digitalized production with a variety of imported automated equipment to monitor the production process in real time, reducing energy consumption and increasing production efficiency. Meanwhile, we utilize a mature waste recycling system during the production process to reduce the generation of waste and pollution of the environment, effectively reducing the burden on the environment.

Choosing the WASUNG Sustainability Path

We encourage our customers to join the sustainability bandwagon in their purchasing and usage processes. By choosing our eco-friendly products, customers can improve the green compliance of their supply chain.

Our products comply with a number of international environmental certifications, such as CE certification, UL certification and ISO 14001 certification, helping our customers to meet the requirements of green procurement policies while complying with industry standards.

We will continue to invest in R&D to promote the innovation of green products and green technologies, and endeavor to provide more environmentally friendly and energy-saving solutions in the field of electrical components.