Quality Control

Retain Customers with High-quality Products

Since its establishment in 1997, we firmly believe that every rubber cable, PVC cable, power cord, electronic wire, plug and connector product carries the trust and safety of our customers. That’s why we have established a strict quality management system to ensure that every product meets the highest domestic and international standards from raw material entry to finished product exit.

Quality Management and Regulatory Standards

Quality management runs through every aspect of production. We have obtained authoritative certifications such as ISO 9001, ISO 45001, ISO 14001, and ISO 17025, and strictly comply with RoHS REACH, TPCH SOR/2012-285, Canada SOR/2016-193, SFS 2016:1067, CPSC 16, International and domestic standards such as SOR/2018-83 and CFR 1303 in Canada. Each process has strict testing and auditing to ensure that the product is always stable and reliable.

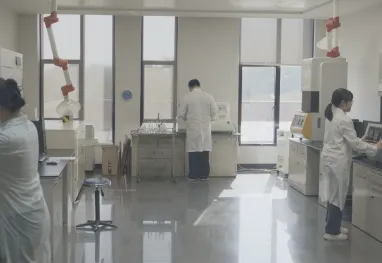

Testing Center and Technical Equipment

We are proud to have a laboratory testing center certified by CNAS, equipped with internationally leading high-precision testing instruments, providing full quality monitoring for every batch of products. These advanced instruments and strict testing processes enable us to comprehensively monitor product quality and provide customers with high-quality products that are safe, environmentally friendly, and energy-efficient The main equipment includes:

High-Frequency Plasma Emission Spectrometer

Accurately detects the elemental content in samples, ensuring that product composition meets stringent standards.

Energy Dispersive X-ray Fluorescence Spectrometer

Performs rapid, non-destructive analysis of the elemental distribution in samples, providing essential data support for environmental protection and safety.

Gas Chromatography-Mass Spectrometry (GC-MS)

Separates and conducts qualitative as well as quantitative analysis of complex chemical components, ensuring the precise detection of trace harmful substances in products.

Ultraviolet Testing Instrument

Focuses on assessing product performance under UV exposure, ensuring excellent weather resistance and stability.

Quality Inspection Process

Our quality control process roughly covers the following processes:

Raw Material Inspection

Strictly screen suppliers and conduct comprehensive testing on each batch of raw materials to ensure impeccable production foundation.

Production Process Monitoring

Real time monitoring of production processes using high-precision instruments to ensure that each step meets predetermined standards.

Finished Product Testing

The finished product needs to undergo multiple strict tests such as electrical performance, durability, and environmental indicators before leaving the factory.

Packaging and Factory Audit

Conduct a comprehensive inspection of packaging and related documents to ensure that every product received by the customer is flawless.